Rakentaminen ja tehdasteollisuus, eli teollinen tuotanto, ovat yhteiskuntamme keskeisiä toimialoja. Niiden lähtöasetanta, tavoitteet, toimintalogiikat ja hallintamallit eroavat kuitenkin toisistaan merkittävästi….

Tekijät | Authors

Tackling the World´s Water Crisis through Solar-powered Water Purification Technology

Water scarcity is one of the fastest-growing global crises and threating the lives of millions. Many drought-stricken areas have no clean drinking water and existing resources are contaminated or high-saline. A technology using reverse osmosis and solar photovoltaic energy has been developed in Finland. This technology turns energy-intensive desalination into affordable and sustainable process.

Water scarcity is one of the fastest-growing global crises and it threatens the lives of millions. Many drought-stricken areas have no clean drinking water and existing resources are contaminated or high-saline. Conventional water purification solutions are expensive, energy-intensive and unable to perform in off-grid locations sustainably. The Finnish company Solar Water Solutions has developed a technology which offers a solution to the global water crisis. The reverse osmosis-based innovation utilizes 100% solar photovoltaic energy without any batteries, and turns energy-intensive desalination into an affordable and sustainable process. Mechanical and electrical engineering has culminated into patented technology, which keeps the pressure constant in varying sunshine conditions. This makes it ideal in rural and remote off-grid areas with near zero CO2 emissions.

Increased water scarcity requires urgent action

Water is a very basic human need and essential for all life. More than 2 billion people globally lack access to safe drinking water and are forced to use contaminated water to survive. Contaminated water is a health risk and it may contain dangerous substances such as chemical poisons and pollution, heavy metals, viruses, bacteria and parasites. The consumption of contaminated water transmits diseases, causes millions of deaths annually and hundreds of millions of people need medical treatment. (World Health Organization, 2019)

Every nation and continent is already affected by global warming. Water scarcity and the sea level rise are one of the most severe effects of it and considered as a global water crisis. The 17 most water-stressed countries in the world are facing extremely insufficient levels of water resources and these countries serve home to a quarter of the world’s population. (World Resources Institute, 2019) It is estimated that by 2025, half of the world’s population is likely to live in water-stressed areas. This is caused not only by global warming but also by uncontrolled population growth in water-stressed developing countries. (World Health Organization, 2019)

Drought is one the main causes of water scarcity. Drought is also affecting agriculture; already in 2013, a quarter of the world’s crops were grown in severely water-stressed areas. Crop irrigation in areas under serious water stress produces over 40% of global food supply and 56% of the world’s cropland is irrigated in extremely water stressed areas. (World Resource Institute, 2019)

Human action based climate change has affected the evolution of droughts since 1900. Dry regions have gotten drier and desertification is turning drying lands into deserts. Meanwhile, many wet regions are getting even wetter and some areas are turning uninhabitable due to decreasing land area. (Columbia University Earth Institute, 2019)

Technology behind the solution

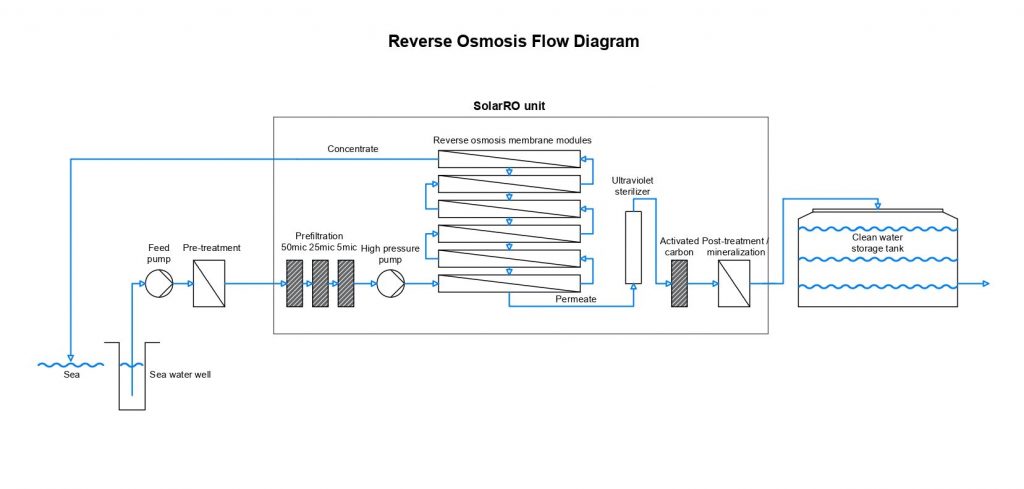

Desalination to turn saline water into potable is used in many parts of the world where access to clean and fresh water resources is limited. Reverse osmosis technology (RO) is a membrane passing process used to separate dissolved solutes like salt, chemicals and impurities from clean water. It is the only available membrane technology able to remove the smallest of dissolved particles like salt (NaCl). (Crittenden et al. 2012)

In the RO process system, pressure needs to exceed the osmotic pressure of the feed water to prevent osmosis and reach reverse osmosis through a membrane (Burn, S. & Gray, S. 2015, 5 9). Feed water is pumped into a partially permeable membrane which then produces clean water (permeate) and concentrate (brine) under pressure. Permeate is collected ready to potable use or further processing which may involve activated carbon filtration or mineralization. All the dissolved solutes of the feed water are concentrated into brine which is flushed away by the membrane and never mixed with the permeate. The RO process requires stable and constant pressure to operate correctly and the quality of the feed water determines the required pressure level to reach the desired permeate production capacity. Higher pressure needs to be used for higher salinity, which also means higher energy consumption. (Crittenden et al. 2012)

SolarRO PRO 1500 flow diagram example

New era of desalination offers sustainable solution

Reverse osmosis is an energy-intensive process which requires constant high pressure to function properly. A conventional desalination system needs constant electrical power from the AC grid, diesel generator or batteries to run a desalination system and maintain the pressure at desired level. Conventional systems cannot be run directly with solar panels, because the amount of available solar energy varies constantly and leads to excessive pressure differences during the process. This leads to decreased clean water production and unstable use of the system. A conventional electrical infrastructure is also unable to use a variable high voltage DC load, which could be used in SWS systems.

SWS (Solar Water Solutions) has developed a patented technology to keep the pressure constant from sunrise to sunset. The ANVS technology allows water flow to differ while pressure stays stable the whole time and clean water production continues through changes in weather and the available energy. This means that clean water production increases linearly with the solar irradiance. A conventional reverse osmosis system will stop or face tremendous drop in the permeate production right after a small decrease in energy supply, because the system cannot adapt to differences in the energy supply or pressure. SWS systems can adapt to the high differences in weather and energy supply and keep the pressure suitable for permeate production. This invention allows the clean water to be produced all day.

SWS system turns seawater from the Atlantic Ocean into drinking and irrigation water with direct solar photovoltaic energy.

Process and system requirements

Raw water is pumped from the raw water source like a well, river or sea and is treated first in pre-filters to remove the largest particles. RO membranes are super thin and sensitive to blockage if the micron size of dissolved solutes exceed 5 microns. Raw water is then directed to RO membranes through a high-pressure pump, which will generate the operational pressure of the RO system. Pressure is generated only on the concentrate side of the system and the pressure control is based on mechanical solution to avoid the sensitivity of electronic parts. Permeate is collected and directed through activated carbon filtration to reduce any odour or taste if necessary. Permeate is then treated a second time for precaution with an ultraviolet sterilizer which kills bacteria and viruses before supplying the water for general use. Concentrated brine contains higher amounts of dissolved solutes than the feed water but is still cleaner than the source and in some cases, may be used for saltwater irrigation, washing or animal use.

The recovery rate tells the percentage of produced permeate from feed water, which is normally around 45 to 55%. For higher conversion demand brine may be used to produce more permeate through an energy recovery system if water sources are scarce, giving a recovery rate up to 75%. The energy recovery system mixes a proportion of brine with feed water and thus gives the system a higher recovery rate. At first, brine increases the TDS level (total dissolved solids) of feed water parabolically, but eventually the TDS stabilizes to a certain level. The recovery system may be suitable in certain locations, but it may also reduce the lifetime of membranes, since more dissolved solutes build up to the surface of membranes over time.

High-salinity water sets high quality requirements for components. Brackish water systems need to be able to fully operate under a pressure of 25 bars and saltwater systems under a pressure as high as 60 bars. All the materials on the pressure side must be strong enough, for example 316L, or even super-duplex to perform as designed without corrosion or leakage problems. An RO pump is capable to withstand dry running without breaking in case of feed water supply malfunction an also made of super-duplex and is specially designed for high-salinity liquids.

System and component protection is a key element for autonomous stand-alone operation and an important R&D section the company pushes forward. One of the protective features is an electrically operated dry run protection which shuts down the system if system pressure falls below the lower limit. For reliable run and metering, all sensors and components have been selected with care after a testing period in actual use.

Electrical design behind the power

Solar-powered hybrid systems are the company’s area of expertise and require water-, energy-, electrical- and IoT technology design and development.

Electrical infrastructure of RO systems combines an AC power source (230–400 VAC) and a high voltage DC power source (up to 800 VDC) with a 24 VDC control circuit into one hybrid system by having full support to both AC and DC power. Electrical protection is designed for both AC and DC circuits separately with fuses, circuit breakers, surge arresters and groundings. For easy use and operation, one main switch is used for selecting AC or DC power and shutting down both as well. Support for AC and DC voltage sets high compatibility requirements for the main switch and especially high DC voltage outlines most of the typical switch types to be used.

A variable-frequency solar drive is used to operate and control the system. The solar drive communicates with all electric components and factors affecting the system operation. The drive is selected for each model based on power requirements of the system motor or motors. Multimotor drive function is included for simultaneous driving of the feed water pump and RO pump.

Solar irradiance is the key factor in system operation when the system is run on solar power. The drive is programmed to let the system start after a certain irradiance level is reached to avoid system underperformance during low voltage times like early mornings. The system also shuts down when irradiance drops under the limit.

Control circuit (24 VDC) combines the solar drive and external start and stop functions, making the whole system operate autonomously. The control circuit consists of external commands like water tank level switch and system pressure switch to start and stop the operation. These sensors together with the solar irradiance level and drive fault tracking control the system without a need for on-site manual controlling.

Electromagnetic interference (EMI) needs to be considered in electrical design and wiring. A low-voltage control circuit is routed separately with high-voltage power circuits to prevent any electromagnetic interference during system operation, which could harm electric operations.

One of the most recent features is the Intelligent Remote Monitoring System (IRM), which is specially designed and coded for these RO systems. In order to stay on track and ensure safe and sustainable RO unit operation, an IRM system can be integrated to any RO unit. IRM captures analytics of the desalination process through a secured live connection to the RO unit and allows the system to be monitored and controlled remotely over long distances, even overseas. IRM collects data directly from the drive and sensors in the system. The communication between drive and IRM gives access to deep operational data, fault tracking and tools to make system parameter changes in real-time. 24 VDC sensors and electronic components operate in the range of 0–20 mA and are separately routed from other more powerful components.

Tech of tomorrow turns obsolete without continuous engineering

For a truly advanced product and company, research and development of improvements never stops. While whole new ideas are on the drawing board, majority of innovations are based on identified development sections, often discovered in actual system operation conditions. Gathering foreknowledge of client destinations is highly important in precise planning and system optimizing. When I first started in Solar Water Solutions, I had no further knowledge of water treatment technology than one semester of water treatment courses and one semester as a trainee in environmental organization in Southern Africa. In 1,5 years, I have grown from a student to an expert and learned to put my focus on the best of my abilities to truly understand clients’ needs and local circumstances in order to engineer the technology that suits these circumstances in the best possible way. Those lessons have come especially important when the operation locations are remote, and the product provides people something essential like access to clean water.

Sources

Baker, R. 2012. Membrane Technology and Applications. New Jersey. John Wiley and Sons, Inc. Referenced 14.9.2019. https://ebookcentral.proquest.com/lib/turkuamk-ebooks/detail.action?docID=977928

Burn, S. & Gray, S. 2015. Efficient Desalination by Reverse Osmosis: A guide to RO practice. Referenced 14.9.2019. https://ebookcentral.proquest.com/lib/turkuamk-ebooks/detail.action?docID=4354916

Columbia University Earth Institute 2019. Scientists See Fingerprint of Warming Climate on Droughts Going Back to 1900. Referenced 10.9.2019. https://blogs.ei.columbia.edu/2019/05/01/climate-change-drought-patterns-1900/

Crittenden, J.; Trussel, R. Hand, D. Howe, K. & Tchobanoglous, G. 2012. Reverse

Osmosis. New Jersey. John Wiley and Sons, Inc. Referenced 14.9.2019. https://ebookcentral.proquest.com/lib/turkuamk-ebooks/reader.action?docID=817311&query=

Gritzner J. & Peel R. 2019. Sahara Desert, Africa. Referenced 10.9.2019. https://www.britannica.com/place/Sahara-desert-Africa

World Health Organization 2019. Drinking-water. Referenced 30.6.2019. https://www.who.int/news-room/fact-sheets/detail/drinking-water

World Resources Institute 2019. One-Quarter of World’s agriculture Grows in Highly Water-Stressed Areas. Referenced 10.9.2019. https://www.wri.org/blog/2013/10/one-quarter-world-s-agriculture-grows-highly-water-stressed-areas

World Resources Institute 2019. Updated Global Water Risk Atlas Reveals Top Water-Stressed Countries and States. Referenced 10.9.2019. https://www.wri.org/news/2019/08/release-updated-global-water-risk-atlas-reveals-top-water-stressed-countries-and-states

This article has been as a part of energy and environmental technology studies and thesis. The author works as a Product Specialist in the company and my area of expertise and responsibility is electrical design of the systems. While production and R&D facilities stands in Espoo, the purification units are delivered worldwide from Eastern Africa to South America solving clean water shortages.